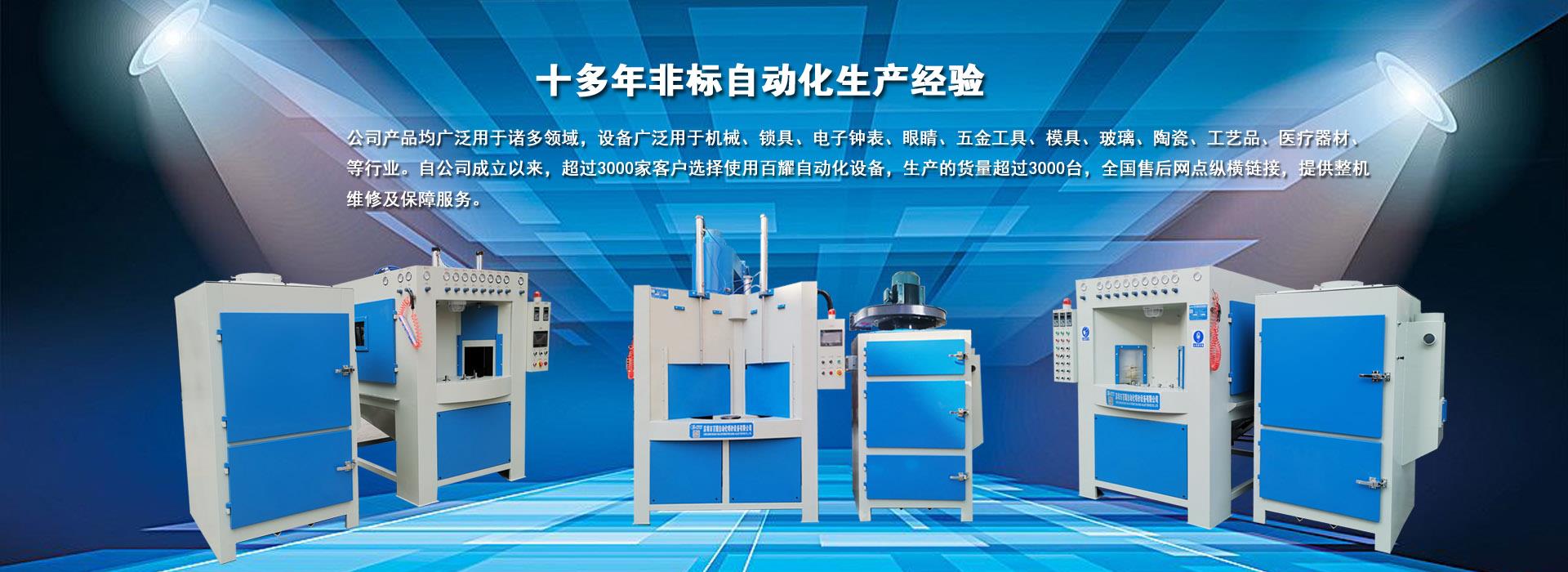

Automatic sandblasting machine

Advantages of automatic sandblasting machine: can be customized according to the product size, 4, 6, 8, 12, 16 guns, etc.

Automatic sandblasting machineSales have been very hot in recent years, so what are the advantages of this machine? You can see it in construction sites and agriculture. Here, let everyone see the difference of the automatic sandblasting machine.

1. Use an automatic sandblasting machine for work. Its advantage is: it can swing automatically, unlike some manual machines. When working, we need to move it with extra force, but this machine avoids this. This kind of trouble, you can work freely just by pressing the switch.

2. It also has an automatic dust removal function. Of course, these operations only require us to press the switch to command it to operate. You don't need to waste your energy, you can save a lot of things!

The parts of the automatic sandblasting machine are of good quality and will not be easily damaged. This automatic machine is not like a manual machine. With a manual machine, we need additional switching, which will cause us a lot of trouble. But when using this machine, there won’t be so many troubles. Moreover, the automatic sandblasting machine is completely in operation. You only need to press a few times. The quality of each part of the automatic sandblasting machine itself It is very good. In the process of using, there is no special worry: there will be some other quality problems, such as wear and tear, because the parts are well made, and the machine will not wear out for a long time.

Automatic sandblasting machine is a kind of cost-effective casting cleaning equipment with modern high efficiency and low investment. Sandblasting machine is usually used for derusting and rusting the surface of easily corrosive materials or workpieces, and deoxidizing non-rusty metals Leather treatment. In daily work, the operating procedures of the sandblasting machine are directly related to the safety of production.

Equipment function

1. Sandblasting equipment is used to clean the surface of the workpiece

Sandblasting equipment can be used for metal corrosion layer, residual salt and oxide layer on the surface of heat-treated parts, oxide layer on the surface of rolled parts, oxide layer on the surface of forged parts, oxide layer on the surface of welding parts, sand and oxide layer on the surface of castings, The residual dirt and tiny burrs on the surface of the machined parts, the surface of the old machine parts, etc. are treated to remove the surface adhesion layer and reveal the nature of the matrix.

2. Sandblasting equipment is used for pretreatment of the workpiece surface before coating

3. Sandblasting equipment can change the physical and mechanical properties of the workpiece

4. Sandblasting equipment is used for finishing the surface of the workpiece

5. The metal parts of the sandblasting equipment are basically not damaged, and the dimensional accuracy will not change;

6. The surface of the part is not contaminated, and the abrasive will not chemically react with the material of the part;

7. The sandblasting equipment can easily handle grooves, recesses and other difficult-to-contact parts, and a variety of abrasives can be selected for use;

8. The processing cost is greatly reduced, which is mainly reflected in the improvement of the work efficiency of the sandblasting equipment, which can meet various surface finishing requirements;

9. Low energy consumption and low cost;

10. The sandblasting equipment does not pollute the environment and saves the cost of environmental treatment;.

Device parameters:

Equipment size

Length 4000mm*width 1500mm high*2800mm

Working cabin size

Length 1200mm*Width 1200mm Height*1200mm

Dust removal box system

Environmental protection filter pulse back blow independent dust box

Dust box size

Length 1000mm*Width 1000mm*Height 2300mm

Control system

Human-machine integrated touch interface

Number of spray guns

Aluminum alloy holster with 12 wear-resistant boron carbide nozzles

Power requirements

380V/50HZ/.9KW

Work requirements

Put before and take after, 2-bit operation

Gas source requirements

Adapt to 75KW-100p screw air compressor-1 nozzle 1m3 flow consumption

Air pressure requirement

0.8 MPa

Product specifications

Products with thickness greater than 0.8mm-length less than 4000mm-width less than 800mm can be processed

Functional Overview

All flat workpieces or plates are discharged from the inlet end and conveyed through the assembly line by the swing spray gun assembly assembly to achieve the overall coverage of the flat workpieces and uniform sandblasting at the concave and convex dead corners.

Application products: heterosexual flat workpieces, gas stoves, suitcases, notebook shells, mobile phone shells, flat glass, heating plates, stainless steel locks, display shell frames, TV shells, computer mainframes, marble plates, aluminum alloy planes, aluminum profiles Plane, engine head accessories, ceiling lights, plane molds, keyboard bases, non-stick pans, pans, sinks, dining tables, wood panels, background walls, solar panels, plane jade, aluminum-plastic panels, titanium panels, organic panels, composite panels, Plastic boards, sign boards, billboards, circuit boards, flat concave-convex auto parts, communication equipment, etc.

Installation Notes:

(1) Choose a site: The sandblasting machine should be installed in a well-ventilated, dry site, with a power supply and a convenient air source.

(2) Select the power supply: the power supply used by the sandblasting machine is AC380V, 50HZ alternating current, and the power switch adopts 4P, 40A air switch.

(3) Select the air source: The air inlet pipe of the sandblaster should be supplied with an imported explosion-proof pipe over 1 inch, and the air source should be dry and clean.

(4) The site, power supply, and air source are ready. Please check the screws and parts of the machine to see if there is any looseness or damage. If so, please fix it firmly or update the new product.

(5) Place the dust collector on the back of the main unit, and connect the dust suction tube and power supply to the main unit.

(6) Connect the compressed air. (7) Switch on the main power supply. (8) The installation is complete.