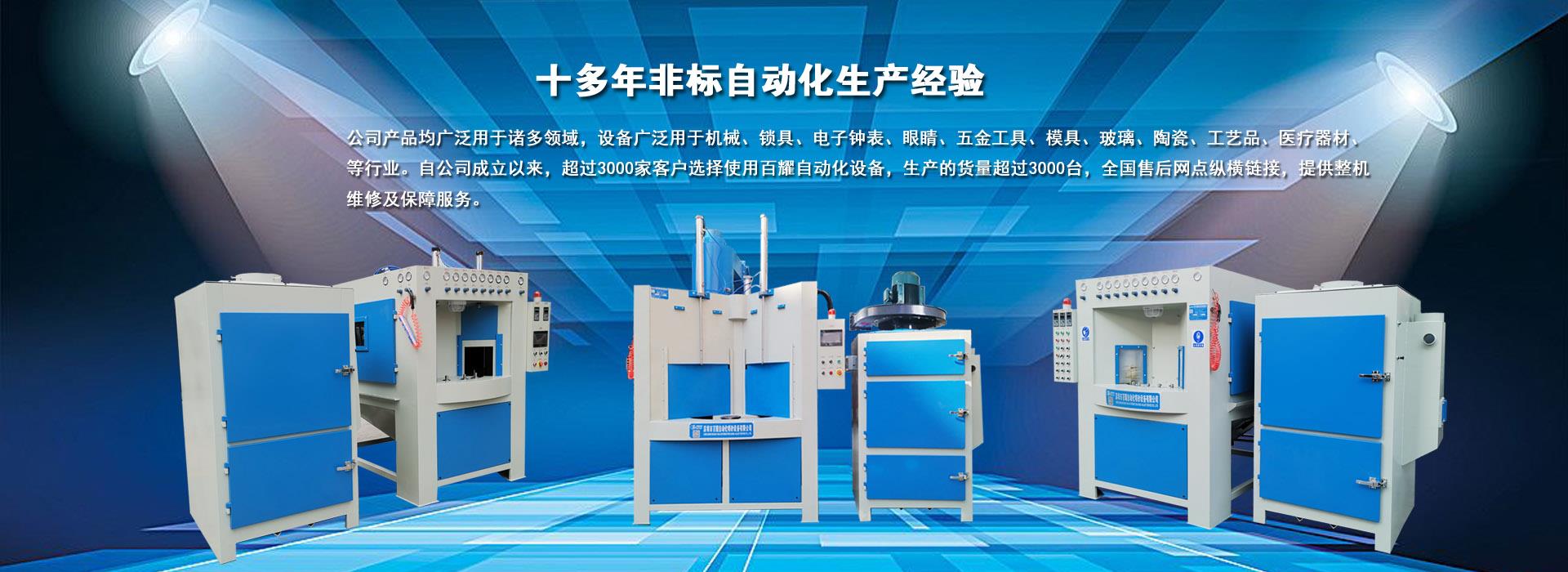

Conveying automatic sandblasting machine

Basic parameters of 1200MM wide 16 spray guns

The machine structure is welded with 2.5MM-6MM steel plate.

Equipment dimensions: 4200mm long 1200mm wide 3000mm high

Equipment working room size: 1200mm long*1200mm wide*1000 high

Dust removal box: 1200mm long*1200mm wide*2000 high

Fan power: 7.5KW

Automatic conveying mechanism: 0.75KW 380V 50HZ [speed adjustable]

1220*3400mm in the middle of the conveying mechanism is a triangle belt,

Automatic gun holder: 0.55KW 380V 50HZ [speed adjustable]

Lighting: The 18w fluorescent lamp 2 uses the upper cyclone sand separation system to directly pump the sand blasting, that is, the compressed air flows in the spray gun at high speed to form a negative pressure to generate the ejection effect, and the sand in the cyclone separator is sucked into the spray gun through the sand pipe Inside, and then sprayed to the surface of the workpiece by the nozzle at high speed with the compressed air flow,

Number of guns: 16 (aluminum alloy with carbonized nozzle)

Perspective window: 1 frame

Sand bucket: 3

Doors: two, front and rear doors opening 800mm high * 700mm wide

Practical use: 30 mesh -120 mesh abrasive

The air pressure is greater than 5bar (kg/cm2) ([Air compressor is above 16 cubic meters] [Air consumption requires 1 cubic meter per gun]

Maximum load capacity in the working room: 120 kg

Total power: about 9.75KW

Can be customized according to customer needs:

Automatic sand blasting machine with 6 spray guns, automatic sand blasting machine with 8 spray guns. 10 spray guns

The working principle of the equipment:

This machine adopts suction sand blasting, which uses compressed air to flow at high speed in the spray gun to form negative pressure to produce the ejection effect. The abrasive in the cyclone storage tank is sucked into the spray gun through the sand pipe, and then the nozzle is shot at high speed with the compressed air flow. To the surface of the workpiece to achieve the purpose of sandblasting. In the working state, compressed air and sand are sprayed while mixing, so that the compressed air can be fully utilized. The air flow and sand flow are easy to adjust, and the ideal mixing ratio can be obtained. The energy and sand consumption are low and the cleaning efficiency is high. , Suitable for large-area cleaning and treatment of workpiece surfaces in electronics, aircraft, locomotive accessories, hardware, chemical industries and other industries

Conveyor sandblasting machine,

12 spray guns conveying automatic sandblasting machine, 18 spray guns Shenzhen conveying automatic sandblasting machine price:

14 belt type automatic sand blasting machine, 16 plane type automatic sand blasting machine

Automatic sandblasting machine with 6 spray guns, automatic sandblasting machine with 8 spray guns. 10 spray gun conveying sandblasting machine,

12 spray guns conveying automatic sandblasting machine, 18 spray guns Shenzhen conveying automatic sandblasting machine price:

14 belt type automatic sand blasting machine, 16 plane type automatic sand blasting machine

Features of conveyor automatic sandblasting machine:

The V-belt is used to convey the workpiece without sand accumulating. The belt speed can be adjusted according to the requirements of the sandblasting process. The angle of each spray gun can be adjusted freely to realize automatic frequency conversion swing and fixed-point sandblasting. It has strong flexibility and applicability. Wide; adopt advanced cyclone separation system configuration, good dust separation effect, high sandblasting efficiency; adopt PLC electric advanced control system, high degree of automation, good stability, low failure rate; nozzle adopts special high wear-resistant ceramic material, use Long life; independent bag type dust removal system, good dust extraction and ventilation effect; (also optional; pulse filter type dust removal); abrasive recycling adopts a combination of spiral conveying and pneumatic recycling, and the recycling stability is good.

Application scope of automatic sandblasting machine:

Pre-treatment of electroplating and spraying to improve adhesion; heat treatment, descaling, residue removal, rust removal, degreasing, and refurbishment of old parts of various molds, castings, stamping parts, metal and non-metal surfaces; all ceramic products, glass Finishing and atomization of products, plastic products; surface treatment of all metal products, glass, plastic crafts, jewelry, glasses, clocks and watches.

Applicable working conditions

1) Environmental conditions: The machine should work normally under the environmental temperature of -10~+45℃ and relative humidity not more than 85%;

2) Power supply conditions: single-phase AC power supply, 220v, 50Hz, the maximum power of this machine is shown in Table-3;

3) Air source conditions: The gauge pressure of the compressed air connected to the machine is 0.4~0.7MPa, and the compressed air flow rate is not less than 1m3/min.

The user should meet the above conditions on site