Turntable automatic sandblasting machine

Features of rotary automatic sandblasting machine:

1. The rotary table type automatic sandblasting machine is divided into intermittent rotary table type automatic sandblasting machine and continuous rotary table type automatic sandblasting machine. The rotary table type automatic sandblasting machine clamps the workpiece on the small rotary table.

On the disc fixture, when the small assembly plate is driven by the large turntable to move to the sandblasting processing station, the workpiece is driven by the small turntable to rotate slowly, and the spray gun moves up and down in two pairs.

The surface of the processed workpiece is sandblasted. After the processing is completed, the pneumatic door opens automatically. After the picking and placing of the workpiece is completed, press the start button, the big turntable

Rotate and repeat the cycle. The inlet and outlet of the work piece adopts pneumatic lifting door, which can automatically open and close when the work piece enters and exits.

2. The nozzle is made of special high wear-resistant boron carbide material with long service life

3. Automatic intermittent rotation of the turntable (continuous rotation can also be designed) stable operation, stable clamping, and quick and convenient workpiece picking and placing;

4. Special cyclone separation system, high degree of automation, good stability and low failure

5. The PLC electrical control system is adopted to ensure the uniformity of the product sandblasting effect;

6. Independent filter core dust removal system, after careful calculation, good ventilation performance, environmental protection and pollution-free.

Process flow:

BY-1700-8A series sandblasting machine is equipped with 8 spray guns according to customer and process requirements. During the production process, the product is directly placed on the small turntable in the operation area, and the large turntable

Driven and enter the sandblasting room; the product surface is sandblasted by the spray gun, and the spray gun can automatically swing sandblasting during the spraying process, so as to perform comprehensive

Sandblasting. At the same time, a hexagonal drive belt in the machine compartment drives the pulley of the small turntable to make the product form a self-rotating state, forming the sandblasting required by customers

effect. After that, the product enters the dust cover, and the sand on the surface of the product is blown off by the internal air gun. The sand falls into the recycling hopper and is lifted by the wind

Entering the separator, useful sand falls into the lower storage tank to realize the recycling of sand and reduce costs. Unqualified sand is separated by the sand separator into the dust box

Filter dust, environmental protection and pollution-free

working principle:

The main machine is equipped with a big turntable -> 4 small turntables are installed on the big turntable -> the operator installs the product on the small turntable on the workbench during work -> the big turntable has

A separate motor drives the upper small turntable to automatically enter the sandblasting chamber -> After the small turntable enters the sandblasting chamber, the lower pulley touches the small rotating chamber.

The belt of the turntable thus rotates -> the product continuously rotates when the spray gun blasts the product automatically -> the small turntable is output from the large turntable to the worktable after the sandblasting is finished.

Application scope of this machine:

Aluminum pot, aluminum shell, glass cover, non-stick pan, stainless steel hand wash tray, communication equipment and other workpieces.

Production capacity:

The theoretical processing efficiency is 3S/2PCS, and the actual processing efficiency is determined by the shape of the workpiece processed on site and the effect of sandblasting.

Reference standard:

GB/16297-2008 Comprehensive Emission Standard of Air Pollutants

GB/T5226.1-1996 Industrial Machinery Electrical Equipment Part 1: General Technical Conditions

GBZ1-2002 Hygienic Standard for Industrial Enterprises

GB12348-2008 Noise standard at the boundary of industrial enterprises

Dust removal system

This machine is equipped with 6 filter element dust removal boxes, equipped with a Sino-Japanese joint venture PHOENIX brand special dust removal filter element, the filtration efficiency is: 99% greater than 10 micron particles. It can make

The dust and gas are effectively separated, and the dust produced in the work is removed, which greatly reduces the harm to the environment. Its exhaust emissions can reach the national environmental protection emissions

Release standard (GB-/T16157-1996): TSP≤120mg/m3.

The filter element dust collector is composed of a high-efficiency filter element, a blowback filter element mechanism, a centrifugal fan, a dust collecting truck, a body, an air duct, and an air duct elbow.

1) The body is welded by 2.5mm high-quality low-carbon steel plate, and the inner and outer surfaces are painted. Dimensions: 1200mm×1200mm×2400mm.

2), high-efficiency filter φ320×600, a total of 18 pieces. The high-efficiency filter element performs dust removal treatment, and the purification effect meets the national environmental protection standards. 100% for high efficiency filter

Made of polyester fiber material, thickness 0.7mm, air permeability 10um, air resistance 2.98mbar (to ensure that the air flow rate is 40cm/s, the required pressure

2.98mm water column), the maximum temperature resistance is 130 degrees.

3) High-pressure fan, power: 7.5KW, speed: 2900 rpm.

4) The back-blowing filter element mechanism is composed of air storage tank, pulse solenoid valve, air pipe, etc.

5) The dust collecting truck is welded by 2.5mm high-quality low-carbon steel plate, and the surface is painted. Dimensions: 400×400×300 (mm).

6) The wind pipe is connected by PVC pipes, and the surface is painted. The air volume adjustment board is arranged at the elbow of the air duct to adjust the air volume.

7), dust removal method: pulse vibration dust removal.

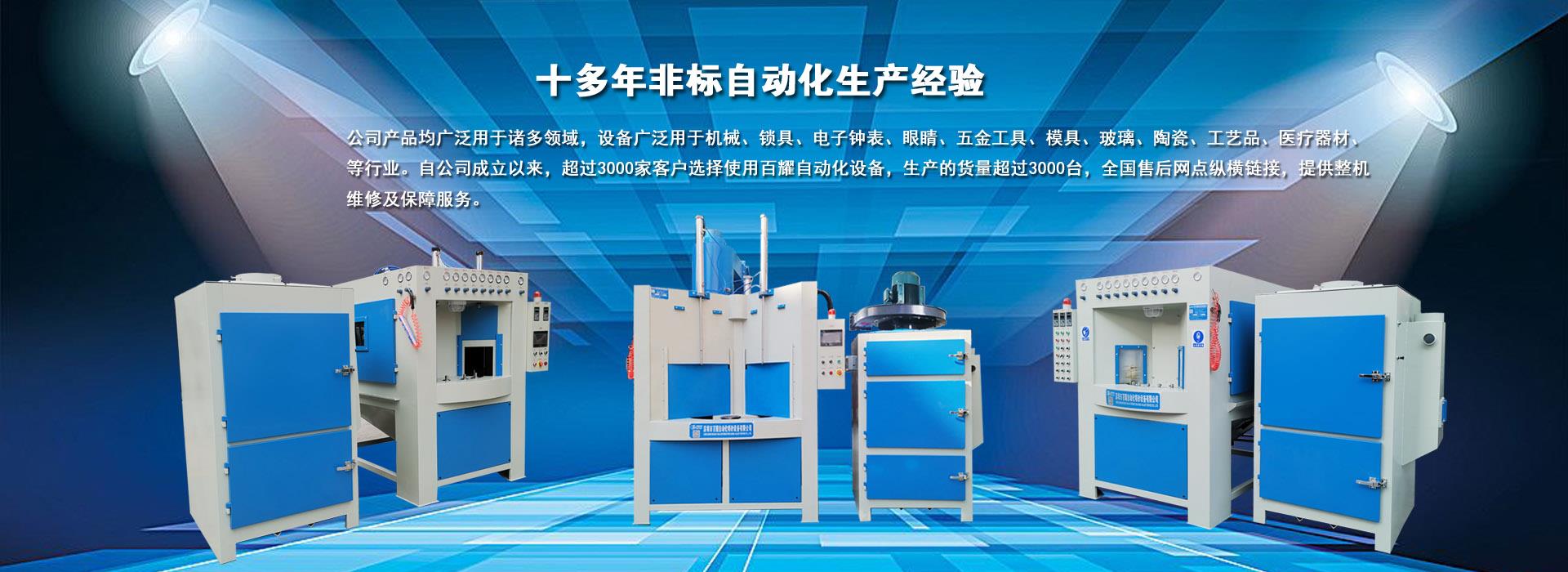

The company is a modern enterprise integrating surface treatment and high-tech research and development, design, manufacturing, and sales. It is also a relatively regular company in the same industry.

Mold strength manufacturer. This technical specification is based on the surface sandblasting characteristics of the product, specially designed rotary disc automatic sandblasting machine, used to sandblast the surface of the workpiece

Treatment, can remove surface bonding lines, flow lines and mold marks, etc.; meet the requirements of deburring, oxide skin, surface finishing, electroplating or spraying on the surface of the workpiece

Pretreatment, eliminating product fatigue and other process requirements. And to design and write.

This equipment is mainly composed of the host, cyclone separator, dust removal system, electrical system, and air compressor (user-provided)