Wet sandblasting machine

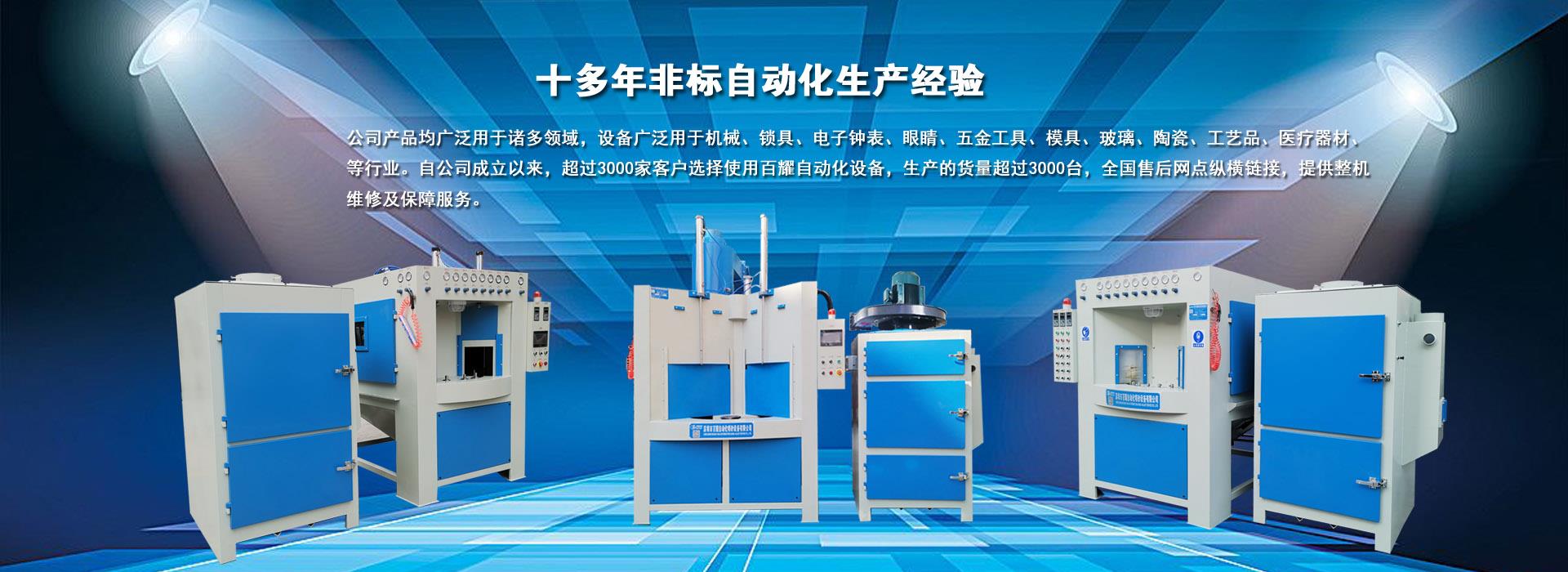

A sandblasting machine and sandblasting machine accessories manufacturer integrating scientific research, development, production, service and sales. After years of hard work, a series of perfect surface treatment equipment has been developed. Developed a series of products such as automatic sandblasting machine, box sandblasting machine, open sandblasting machine, pipeline inner and outer wall sandblasting machine, pneumatic recycling sandblasting room, environmental protection sandblasting machine, etc.

Main technical parameters of stainless steel wet sandblasting machine

Specification Model: BT-9080W

Dimensions: 910*1000*1660mm (length * width * height)

Working chamber size: 900*800*600mm (length*width*height)

Sand pump motor: 220V/50HZ/750W

Sandblasting head: aluminum alloy waterproof nozzle

Stainless steel plate: 2.5mm stainless steel

Air pressure requirement: pressure 7BAR flow 0.4-1.0 cubic meter

typical application

Precision molds, electronic parts, medical equipment, cutting tools and measuring tools, piston rings, aviation parts, aluminum alloy, titanium alloy workpiece surface finishing treatment, circular saw blades and single-piece, small batch sandblasting processing of oily workpieces

Dongguan Baiyao Automatic Sandblasting Equipment Co., Ltd.

The main purpose

--Used for surface cleaning of parts, as well as pre-treatment of coating and flaw detection processes. It can clean oxide scale, residual salt, sand, oil stain, rust, carbon deposit, mold release agent of heat-treated parts, welded parts, castings, forgings, etc. , Welding slag stains, paint film, plating and other contaminants, the cleaning quality can reach Sa3 level, while the active surface can be obtained, and the adhesion of coating and plating can be improved.

--Used to clean up the tiny burrs and surface residues of machined parts.

It is used for the finishing of aluminum castings and stainless steel parts to obtain a matte surface and a diffuse reflection surface; it can be used for printing and engraving decorative surface patterns. The effect of light decoration processing is more delicate and beautiful than dry decoration, which improves product quality.

--Used for finishing processing of parts with high precision, small roughness Ra value, and complex shapes that are difficult to complete by other processing methods.

--Used to improve the physical and mechanical properties of the surface of the workpiece, such as changing the surface stress state to increase the fatigue strength; improving the surface lubrication state of the mating part and the movement conditions of the friction pair, and reducing the operating noise.

--Used to refurbish old parts.

--It is used for mold cleaning, does not damage the surface of the mold, and ensures the accuracy of the mold.