Several environmental protection methods for rust removal and sandblasting machine

At present, in the process of repairing large cabins and hulls of many ship enterprises in my country, copper ore is basically used as abrasive.Rust removal sandblasting machine. But this kind of additionThe rust method will produce large dust floating into the atmosphere, causing serious pollution to the atmosphere; at the same time, the waste sand produced will also pollute the water quality. In order to change the traditional sand-blasting and rust-removing method of rust-removing sandblasting machine, domestic research and application of alternative methods of traditional rust-removing have begun. There are mainly the following:

One is sandblasting + dust-proof net derusting. This method is based on the rust removal sandblasting machine using traditional copper ore as the abrasive, and one or more layers of dust-proof nets are temporarily pulled in the sanding and rust removal area to enclose the sanding area to prevent and reduce sand Drift of dust, thereby reducing air pollution. The dust-proof effect of this method is closely related to the pulling quality of the dust-proof net, which increases labor, material, and time costs.

The second is water mist + sandblasting to remove rust. This method is to modify the traditional rust removal and sandblasting machine. Specifically, it is to transform the sand gun of the sand blasting machine, design and process a part with a certain number of nozzles and water chambers, install it on the sand gun, and then connect the water pipe to the sand gun while blasting and removing rust. Water mist is formed on the periphery, and the combination of water mist and sand dust prevents and reduces the dust from drifting into the atmosphere and reduces air pollution. This method has the problems of rust reversion and secondary rust removal.

The third is to remove rust by mixing water and sand. The method is to design and manufacture a new set of rust-removing sandblasting machine equipment. After ore and water are mixed in the equipment, the sand and water are adjusted to a certain ratio through the associated valve and pump, and then transported to the sand gun for blasting. Sand rust removal. Because it is a mixture of water and sand, the sand and dust produced during the rust removal process will splash and flow down with the water, preventing and reducing the drift of sand and dust, thereby reducing the pollution to the atmosphere. However, the rust removal sandblasting machine also has the problem of secondary rust return, the rust removal efficiency is low, and the sand pipe is easily blocked.

The fourth is ultra-high pressure water rust removal. This method also designs and manufactures a new set of rust-removing sandblasting equipment, the core component of which is an ultra-high pressure pump set. Since water is used to replace traditional copper ore, no sand or dust is generated during the rust removal process, which will not cause air pollution. At the same time, the used water can be recycled after being filtered to reduce pollution to the water source. However, this method has problems such as high purchase cost of rust removal and sandblasting equipment and difficult maintenance.

Previous: No Information

下一条: Classification of dry rust removal sandblasting machine

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

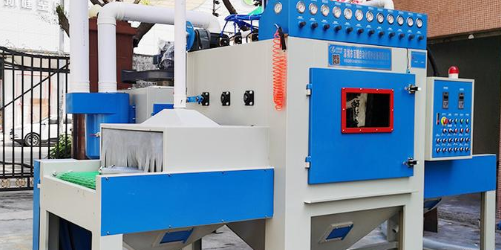

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function