The automatic sandblasting machine is a kind of sandblasting machine, which also uses compressed air as the power and metal abrasive as the medium. The automatic of the automatic sandblasting machine refers to automatic sandblasting, automatic loading and unloading of workpieces, automatic swinging of the spray gun, automatic sorting of abrasives, automatic dust removal, etc. Anyway, except for the up and down of the workpiece, no manual operation is required for the rest.

There are 4 types of automatic sandblasting machines:

1 Conveying automatic sandblasting machine

Conveyor automatic sandblasting machine is also called flat automatic sandblasting machine, assembly line sandblasting machine. It is a high-volume automatic sandblasting machine. The products that need sandblasting are placed on the left side. The automatic conveyor belt will automatically bring the sandblasted products into the blasting room. After the sandblasting is completed, the conveyor belt will take the products Bring it into the blowing room and automatically blow it clean. It is best that the conveyor belt automatically takes the product out and takes it out manually. The whole process is automatically and continuously completed. The user can also match the flow operation according to the actual situation of the factory. In this case, the entire production process can be realized without manual operation.

Conveyor automatic sandblasting machines are generally suitable for products: suitable for sandblasting of flat plates, plates, squares, profiles and other heterogeneous workpieces, such as: flat stainless steel plates, ordinary steel plates, glass steel plates, stone, non-stick pans, Bakeware, toaster, computer case, functional DVD panel, notebook, computer motherboard, decorative parts, package badge, communication equipment, aluminum sheet, profile and other special-shaped parts, etc.

2 Turntable automatic sandblasting machine

Rotary automatic sandblasting machine is also called rotary table automatic sandblasting machine, gap automatic sandblasting machine, continuous automatic sandblasting machine. It is also a high-capacity, high-efficiency automatic sandblasting machine. The large sandblasting turntable is equipped with 8 small turntables, which are divided into 4 areas, sandblasting loading and unloading area, sandblasting to be processed area, sandblasting processing area, and blowing room. Products that require a sandblasting machine are manually placed in the sandblasting loading and unloading area. The big turntable will automatically rotate, and the whole rotation is 360°. Manually only need to stand in the same position to load and unload the product. Users can also configure flow operations according to some of their own output requirements, but the configuration of loading and unloading areas generally requires a manipulator, which is costly.

The rotary automatic sandblasting machine is suitable for the mass production of inner and outer surfaces of discs, cylindrical and square workpieces, such as handicrafts, glass lampshades, non-stick pans, flashlights, bakeware, stainless steel wash basins, communication equipment and other workpieces.

3 Tracked automatic sandblasting machine

Track-type automatic sandblasting machine is also called drum-type automatic sandblasting machine. It is a high-output, high-efficiency automatic sandblasting machine, but this type of sandblasting machine has a disadvantage, that is, the product is afraid of collisions and cannot be used. Manually pour all the products that need sandblasting into the sandblasting room, close the door, set the sandblasting time, after the sandblasting is completed, the machine automatically stops, and manually take out the sandblasted products.

The crawler-type automatic sandblasting machine is suitable for small parts, large-scale production and other workpieces.

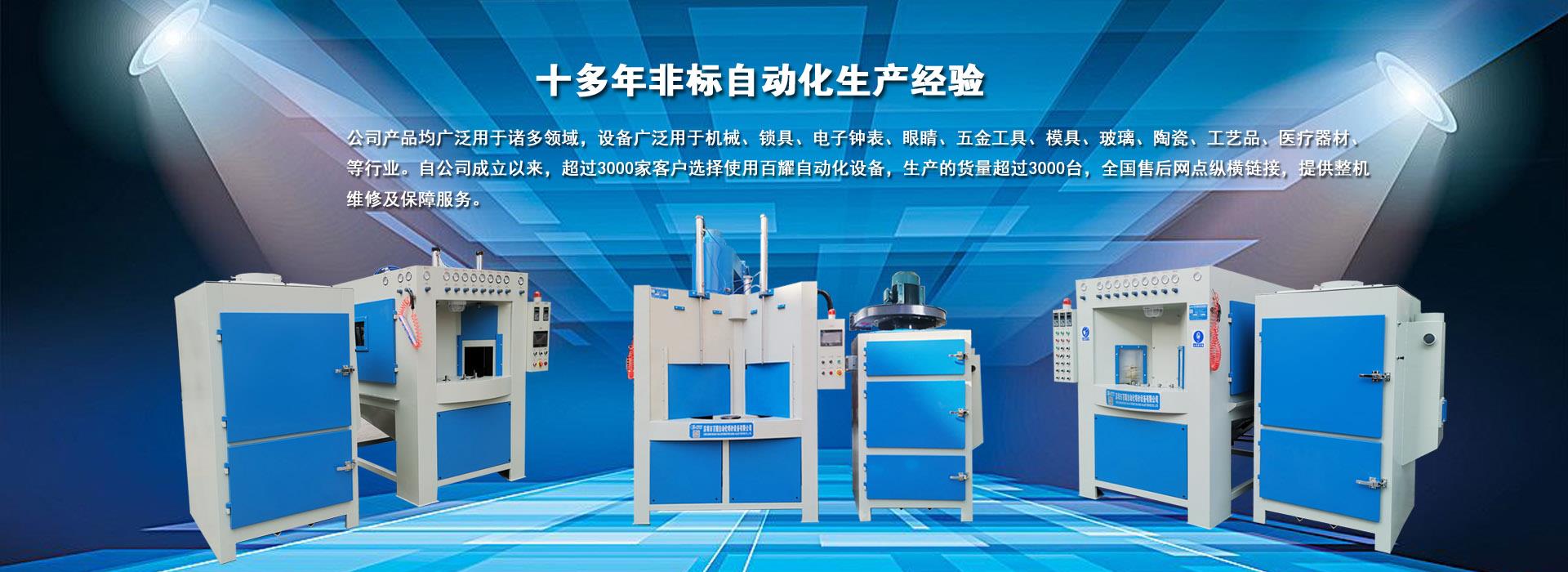

4 Non-standard automatic sandblasting machine

Non-standard automatic sandblasting machine is a kind of sandblasting machine customized according to the user's product, performance, output and other requirements. The transmission method, sand blasting method, sorting method, dust removal method, recycling method of sandblasting machine equipment can be customized according to different.

Non-standard automatic sandblasting machine is suitable for all kinds of products.

Due to the special types of automatic sandblasting machines, it is difficult for many users to distinguish which equipment is more suitable for them and which equipment is more cost-effective for them. As a sandblasting machine industry for more than ten years, I recommend that customers must go to professional manufacturers on site. Investigate to avoid unnecessary losses.

Related Industry Knowledge

- Environmental protection and energy saving sandblasting machine controls dust pollution during the sandblasting process

- Wet blasting machine with abrasive blasting

- Adjustable spray pressure of small sandblasting machine

- Inhalation type sandblasting

- Process parameters of sandblasting machine for composite metal materials

- Design of automatic sandblasting machine with synchronous conveying of shaft inner hole and outer circle

- Talking about the research and optimization status of rust removal and sandblasting process parameters

- Mobile sandblasting machine adopts press-in sandblasting

- Sandblasting machine manufacturers provide a variety of sandblasting machines

- Matters needing attention when sandblasting machine sand blasting cupronickel casing parts

- Overview of burr machine

- The material used for the blasting of the rust removal sandblasting machine is the sandblasting abrasive