Design background and motion system of environmental protection and energy saving sandblasting machine

useEnvironmental protection and energy saving sandblasting machineSandblasting to remove rust is the main method of surface pretreatment for pipeline coating. The patch area of the submarine pipeline is the bottleneck of the entire pipeline for anticorrosion, and the quality of its surface derusting treatment directly affects the frequency of submarine pipeline failure accidents. At present, the use of sandblasting and rust removal technology is gradually restricted due to its serious environmental pollution and endangering human health. Although wet sandblasting and ultra-high pressure water rust removal technology avoid environmental pollution, it is easy to produce floating rust after wet sandblasting. However, the ultra-high pressure water rust removal technology is expensive and cannot be widely adopted. The development of environmental protection and energy saving sandblasting machine provides an effective way to solve the above problems.

The environmental protection and energy-saving sandblasting machine is an automatic rust removal device for pipe joints, which can reduce pollution to the surrounding environment on a larger scale, improve the working environment of workers, increase their work efficiency, and ensure the quality of pipe joints. Since environmental protection and energy-saving sandblasting machines are usually used in environments with very harsh working conditions, this places higher requirements on their control systems. The advantages and disadvantages of the environmental protection and energy-saving sandblasting machine control systems determine the overall performance of the equipment and affect The effect of sandblasting and rust removal.

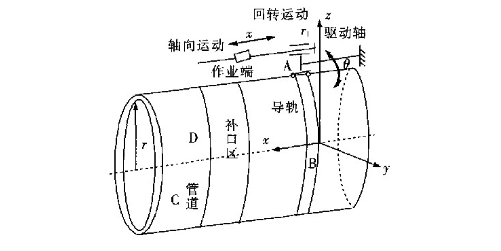

The motion system of the environmentally friendly and energy-saving sandblasting machine can be simplified into a type of tandem mechanism. The structure of the motion system is shown in Figure 1. In the figure, A is the motion system body, B is the moving guide rail of the motion system, C is the pipeline, and D is the sandblasting area. It can be seen from Figure 1 that the feed mode of the motion system includes rotary feed along the orbital direction and axial feed along the pipe axis. When the movement system of the environmental protection and energy-saving sandblasting machine moves in a circular motion along the guide rail, its rotary feed motion can be transformed into a rotary motion around the axis of the pipe, and the radius of rotation is r+r.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- Introduction to the main process parameters of the rotary automatic sandblasting machine

- Structure of mobile sandblasting machine for steel surface

- The working principle of remote control double cylinder double bridge mobile sandblasting machine

- Overview of vertical automatic sandblasting machine

- Overview of sponge abrasive automatic sandblasting machine

- Introduction of rotary automatic sandblasting machine

- Advantages of sponge abrasive low dust environmental protection and energy saving sandblasting machine

- Quality control of rust removal and sandblasting machine in the construction process

- Construction effect of sponge abrasive environmental protection and energy saving sandblasting machine

- The composition of the rotary table automatic sandblasting machine system