The composition of the rotary table automatic sandblasting machine system

Turntable automatic sandblasting machineUse compressed air as power to form a high-speed jet beam and spray abrasives on the threaded surface at high speed. The impact and cutting effect of abrasives on the surface of the workpiece is used to remove dirt and burrs on the thread surface to clean the thread surface, optimize the thread surface performance, and improve the anti-sticking and anti-corrosion performance of the threaded part of the steel pipe. Rotary disc type automatic sandblasting machine is mainly composed of main machine, spray gun moving mechanism, high-efficiency separator, dust removal system, etc.

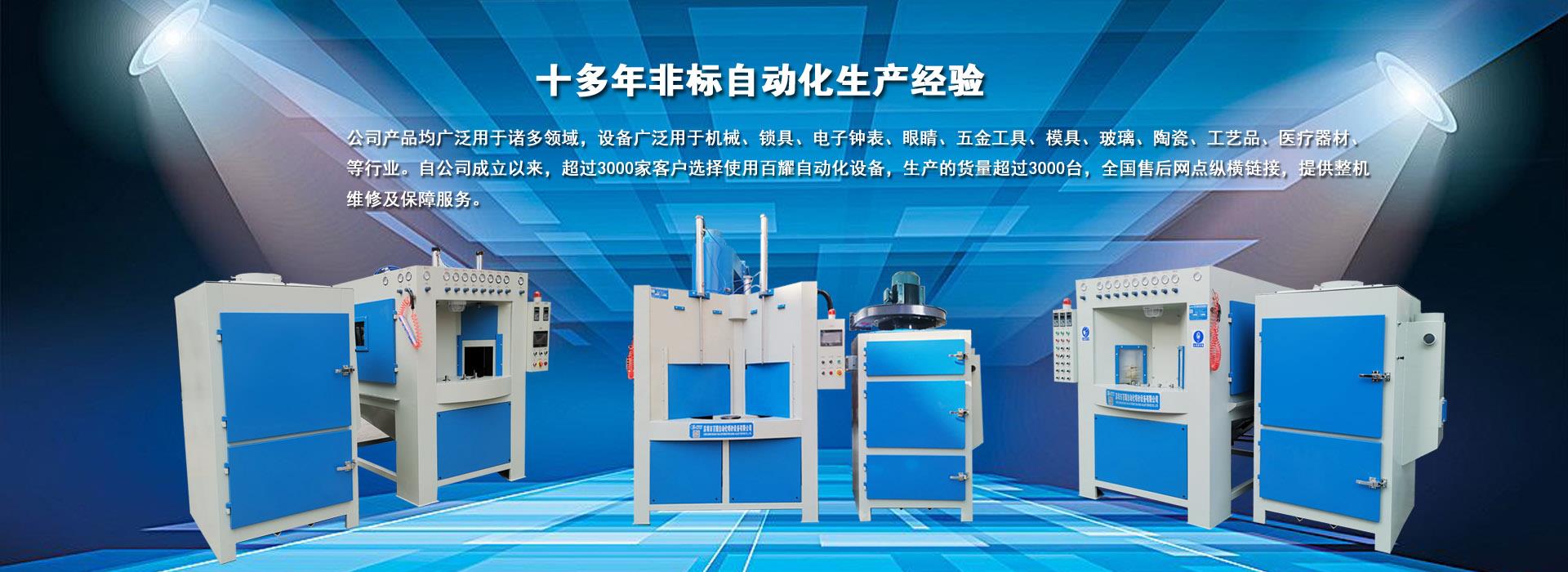

The main body of the rotary automatic sandblasting machine is welded with 10 mm stainless steel plates, and the internal and external surfaces of the engine room are painted. The front of the main machine is equipped with a manual door for easy trimming and replacement of easy-to-use parts. The inner wall of the complete machine room is pasted with protective rubber to protect the box structure from spray damage and effectively reduce noise.

The spray gun moving mechanism of the rotary automatic sandblasting machine is mainly driven by a gas cylinder. The nozzle is equipped with 6 high-efficiency spray guns, which are made of highly wear-resistant hard alloy materials. The high-efficiency separator can effectively separate good abrasives and dust to ensure that the workpiece can be processed efficiently and save more abrasive loss. If the separation effect of the separator is not good, the additional efficiency of the rotary automatic sandblasting machine and the dust removal effect of the whole machine will be affected.

Dust removal system: under the action of the dust removal fan, the rotary disc type automatic sandblasting machine enters the dust-containing gas into the filter cartridge dust collector through the side bottom inlet of the pipe, and then filters upward through the high-precision filter cartridge. Dust is collected on the outer surface of the filter cartridge, and the filtered purified gas enters the clean air chamber through the center of the filter cartridge and is discharged through the outlet pipe of the rotary automatic sandblasting machine. As dust accumulates on the outer surface of the filter cartridge, the resistance of the dust-containing gas through the filter increases accordingly. The pulse blowback instrument equipped with a dust collector controls the pulse solenoid valve to regularly deliver compressed air to each filter cartridge to remove dust on the outer surface of the filter cartridge, avoiding the dust removal system of the rotary automatic sandblasting machine, which reduces dust removal due to high resistance effectiveness.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- The working principle of the moving sandblasting machine system on the inner wall of the pipeline

- Characteristic description of water rust removal sandblasting machine

- Talking about the function and characteristics of wet sandblasting machine

- Function introduction of automatic sandblasting machine

- Talking about the composition of mobile sandblasting machine

- Dust removal status of automatic sandblasting machine

- Composition of mobile sandblasting machine

- Analysis of common design problems of mobile sandblasting machine

- What are the factors that cause the uneven sand density of the automatic sandblasting machine

- Points to note when buying a fully automatic sandblasting machine