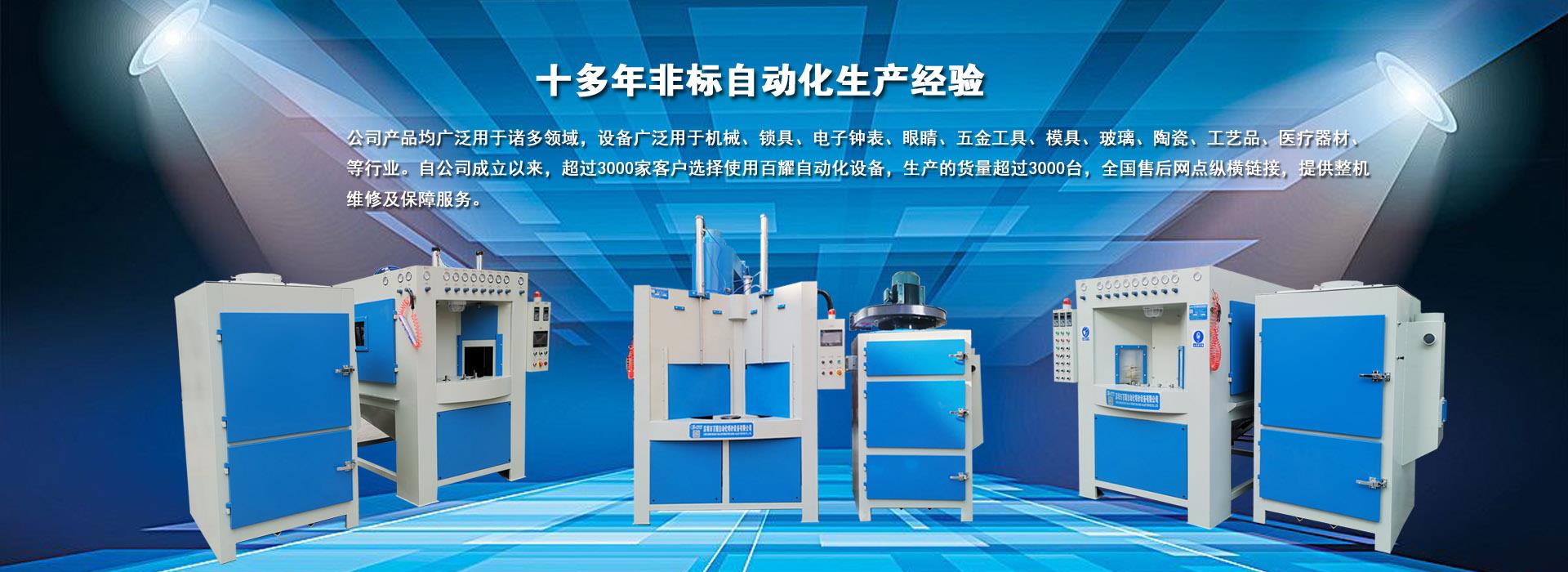

Overview of vertical automatic sandblasting machine

Baiyao automated verticalAutomatic sandblasting machineMainly used for rotating parts such as stepped shafts and roller discs, such as large gears. The so-called vertical type means that the parts that need sandblasting are placed upright in the spray booth inside the equipment, that is, the center line of the parts is perpendicular to the ground. The vertical automatic sandblasting machine can make full use of the space of the sandblasting equipment. The work flow of this sandblasting equipment is briefly introduced below.

Vertical automatic sandblasting machine is a closed processing method. The upper part of the internal spraying room of this sandblasting equipment is provided with a track leading to the outside of the equipment, and the upper part of the track is equipped with a rolling hoisting device, which can load and unload workpieces outside the sandblasting machine equipment. When in use, open the door on the outer wall of the sandblasting machine equipment, move the lifting device to the outside of the equipment, and then hang the parts with the special hoisting tool on the lifting device of the sandblasting machine equipment, and send it to the vertical automatic blasting machine. In the spray room inside the sand machine, then close the door of the spray room. Turn on the power switch, and the parts rotate at a constant speed with the lifting device, just like a ceiling fan installed on the ceiling. At the same time, the spray gun installed on the inner wall of the sandblasting machine is connected to the compressed air, and the negative pressure is used to suck in the top of the equipment. The sand is sprayed on the part. After the sand particles sprayed on the parts fall, they are collected by the funnel below the vertical automatic sandblasting machine equipment, lifted by the screw auger device to the top of the sandblasting machine, and injected into the bin to form a circulation of sand particles.

Baiyao Automation's vertical automatic sandblasting machine is widely used in the sandblasting processing of textile machinery products. Because there are a large number of shaft-type roller-type welded structural parts in such products, as well as parts such as stainless steel tanks, which require sandblasting surface treatment. However, because the vertical automatic sandblasting machine adopts the dry sandblasting method, the dust in the sandblasting process is very large, which will pollute the environment and threaten the health of the operators.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- Overview of sponge abrasive automatic sandblasting machine

- Introduction of rotary automatic sandblasting machine

- Advantages of sponge abrasive low dust environmental protection and energy saving sandblasting machine

- Quality control of rust removal and sandblasting machine in the construction process

- Construction effect of sponge abrasive environmental protection and energy saving sandblasting machine

- The composition of the rotary table automatic sandblasting machine system

- The working principle of the moving sandblasting machine system on the inner wall of the pipeline

- Characteristic description of water rust removal sandblasting machine

- Talking about the function and characteristics of wet sandblasting machine

- Function introduction of automatic sandblasting machine