Introduction of rotary automatic sandblasting machine

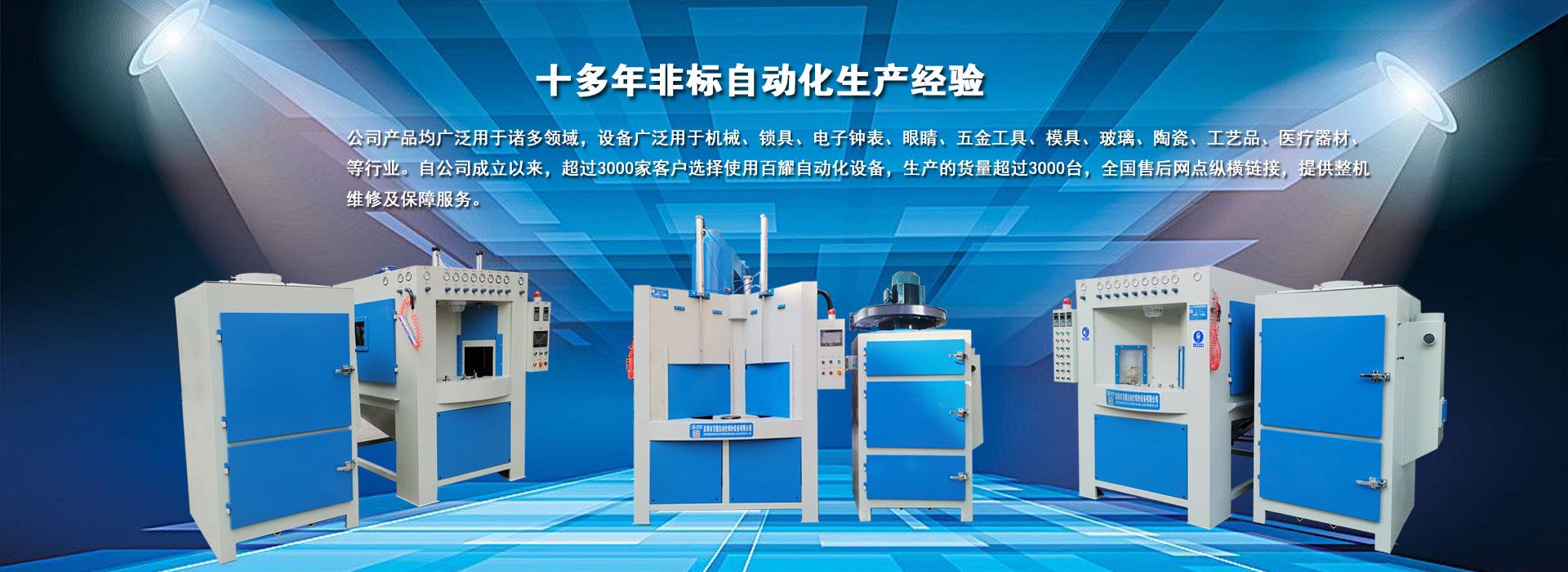

Turntable automatic sandblasting machineIt is a very common type of sandblasting machine in the entire sandblasting industry. It has multiple sandblasting stations, which can process multiple workpieces at the same time, and can also swing at multiple angles so that each surface of the workpiece can be sandblasted. It is generally used for various small hardware Spraying treatment of plastic products and other workpieces. Here is a brief introduction to the rotary automatic sandblasting machine.

Compared with the ordinary sandblasting machine, the rotary automatic sandblasting machine has higher working efficiency and can spray multiple workpieces at the same time. There are 8, 10, 12, 14 and 16 small turntables on the large turntable of the sandblasting machine. These small turntables are divided into 4 areas, namely the sandblasting loading and unloading area, the sandblasting waiting area, the sandblasting area and the cleaning area. room. The operator manually places the products that need to be sandblasted in the sandblasting loading and unloading area. After the placement is complete, the large turntable of the rotary automatic sandblasting machine will automatically rotate 360°. After the products in the loading and unloading area are transported to the sandblasting waiting area, Then return to the same position, so that the operator does not need to move, just stand in the same position to load and unload the blasting products. The rotary automatic sandblasting machine can also be equipped with a manipulator to realize automatic flow operation, but the cost of such a configuration is high. If it is not necessary for general users, it is generally not recommended to configure a manipulator.

In addition, because the rotary automatic sandblasting machine is a non-standard product, this means that it does not have a unified production and evaluation standard. Users are more likely to have disputes when purchasing these equipment. Therefore, users must contact the sandblasting machine manufacturer. Signed a commission to produce a combination, and clearly stipulated the performance indicators of the rotary automatic sandblasting machine, so that later disputes can be reduced, and losses caused by unclear standards can be avoided.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- Advantages of sponge abrasive low dust environmental protection and energy saving sandblasting machine

- Quality control of rust removal and sandblasting machine in the construction process

- Construction effect of sponge abrasive environmental protection and energy saving sandblasting machine

- The composition of the rotary table automatic sandblasting machine system

- The working principle of the moving sandblasting machine system on the inner wall of the pipeline

- Characteristic description of water rust removal sandblasting machine

- Talking about the function and characteristics of wet sandblasting machine

- Function introduction of automatic sandblasting machine

- Talking about the composition of mobile sandblasting machine

- Dust removal status of automatic sandblasting machine