Structure of mobile sandblasting machine for steel surface

For steel surfaceMobile sandblasting machineIt is a kind of equipment specially used for the physical treatment of steel surface. Steel is a kind of metal material with a very wide range of applications, but it is damaged by the chemical and electrochemical effects of the surrounding medium, and the so-called corrosion phenomenon will occur. If these foreign objects are not removed before painting, the coating film will not be able to be removed. Curing or causing the coating film to crack or peel, especially the rust will continue to expand under the film and lose the meaning of coating. The mobile sandblasting machine on the steel surface can remove the scale, rust, grease, dust and other dirt attached to the surface, so that the steel surface can be repainted. Here is a brief introduction to the structure of this device.

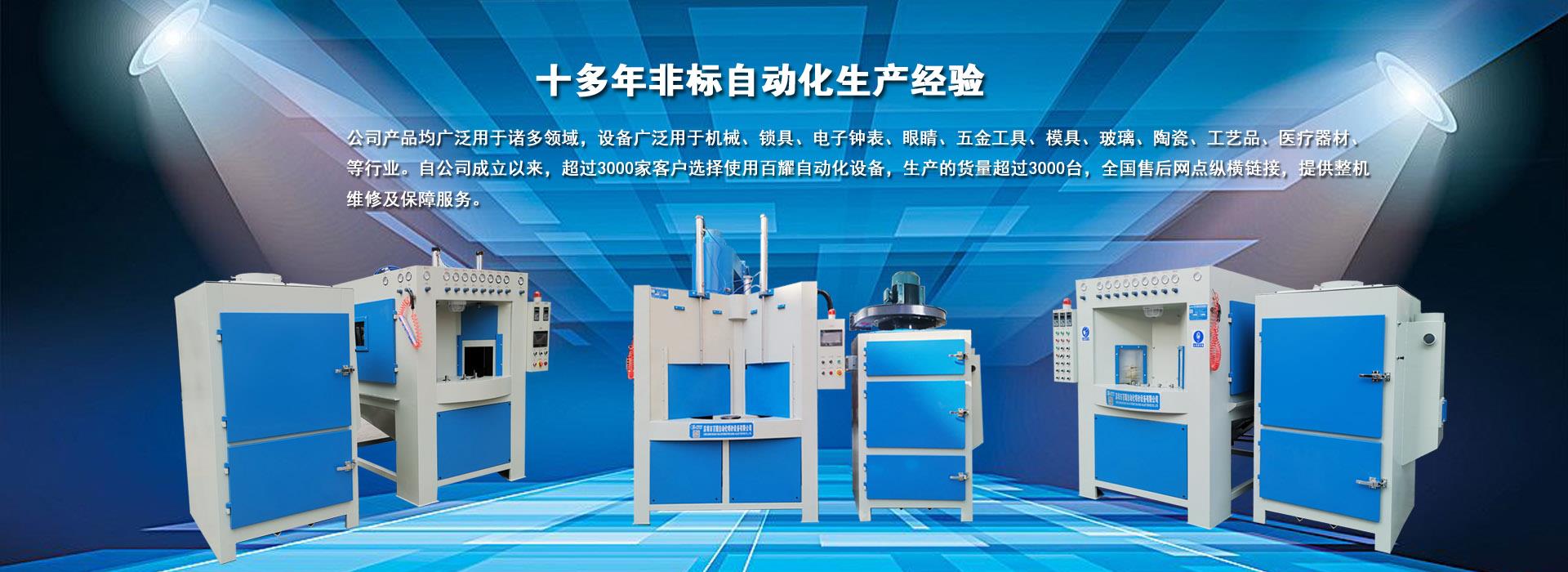

The mobile sand blasting and suction machine for steel surface is composed of 4 sets of sand blasting systems, 2 sets of continuous suction and release sand buckets, bucket elevators, pill dust separator and dust removal system, pill storage box, air storage bag, and electronic control gas Control system and other components. These parts are very compactly installed on the frame that is convenient for hoisting, and can be hoisted and moved, making the entire sandblasting operation flexible and convenient. In addition, the mobile sandblasting machine for steel surface is also equipped with 2 high-performance vacuum sand suction machines to generate vacuum suction for sand and dust suction, and 4 movable sand collecting buckets for revolving storage of abrasives. When lifting and moving, reduce the overall weight and try to avoid full-load lifting.

The vacuum sand suction dust removal device of this mobile sandblasting machine can recover other abrasives such as steel grit or steel shot accumulated in the cabin. Its components are: cyclone dust collector, filter cartridge dust collector, muffler, vacuum pump, motor, electric control The box is a whole, compactly installed on a frame that is convenient for hoisting. In addition, each vacuum sand suction device of the mobile sandblasting machine is equipped with a movable sand collecting bucket and a vacuum tube with a diameter of 6 inches.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- The working principle of remote control double cylinder double bridge mobile sandblasting machine

- Overview of vertical automatic sandblasting machine

- Overview of sponge abrasive automatic sandblasting machine

- Introduction of rotary automatic sandblasting machine

- Advantages of sponge abrasive low dust environmental protection and energy saving sandblasting machine

- Quality control of rust removal and sandblasting machine in the construction process

- Construction effect of sponge abrasive environmental protection and energy saving sandblasting machine

- The composition of the rotary table automatic sandblasting machine system

- The working principle of the moving sandblasting machine system on the inner wall of the pipeline

- Characteristic description of water rust removal sandblasting machine