Safety operation specification of automatic derusting sandblasting machine

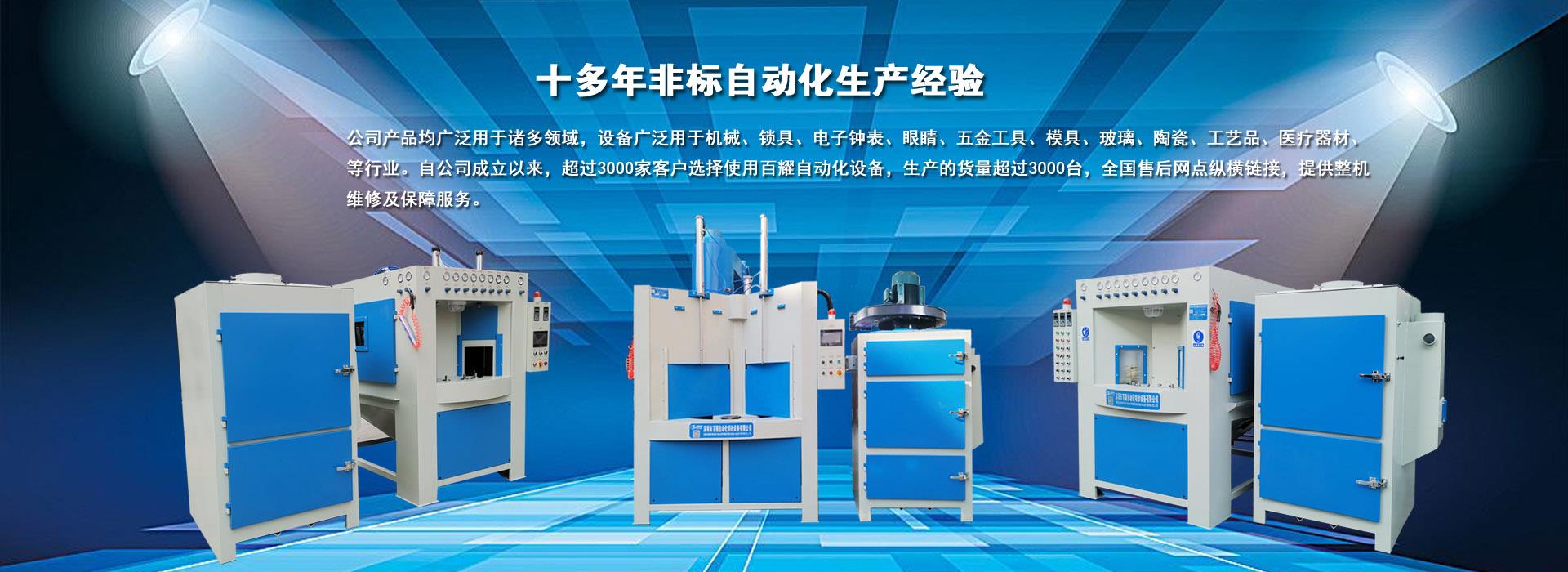

Automatic derusting and sandblasting machineDifferent from other surface treatment equipment, it is a cost-effective surface cleaning equipment with higher surface treatment efficiency and lower price. It is usually applied to the surface derusting and derusting of easily corrosive materials or workpieces, and the deoxidizing treatment of non-rusting metals. In daily work, the operating procedures of the automatic derusting and sandblasting machine are very important. It is directly related to whether safe production can be carried out. Here is a brief introduction to its safe operating procedures.

The safe operation specifications of the automatic rust removal sandblasting machine are as follows:

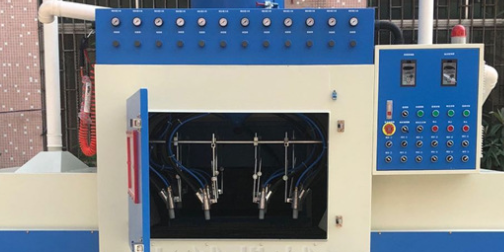

1. The gas storage tanks, pressure gauges, safety valves and other parts of the automatic rust-removing sandblasting machine with major safety risks must be checked regularly to ensure that the equipment is always in a safe and controllable state. The specific measures are as follows: the gas storage tank shall discharge dust every two weeks, the filter in the sand tank shall be checked once a month, and the pressure gauge and safety valve shall be checked once every two weeks to see if it is normal.

2. Check whether the ventilation pipe and door of the automatic derusting and sandblasting machine are in a sealed state. Every time five minutes before the equipment is started, its ventilation and dust removal device must be activated first. If the ventilation and dust removal device fails or fails, the sandblasting machine must not be started to avoid damage to the equipment.

3. Before performing sand blasting operations, the relevant operators must wear protective equipment. It is particularly important to note that they cannot take off the protective equipment privately for the operation of the automatic rust removal and sand blasting machine due to hot weather and airtightness. It will not only cause great safety hazards, but even lead to safety accidents.

In addition, the automatic derusting and sandblasting machine needs to pay attention to the operation: the opening speed of the compressed air valve should not be too fast, so as to avoid the air pressure rising too fast, the air pressure should generally be controlled at 0.8MPa; the particle size of the abrasive should be adapted to the workpiece Applicable between 10th and 20th, sand should be kept dry. When the automatic descaling and sandblasting machine is working, no unrelated persons are allowed to approach it. When cleaning the equipment and adjusting the operating parts, it should be carried out in a stopped state.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- Application of rust removal and sandblasting machine in steel beam sandblasting and rust removal

- Introduction to the main performance and characteristics of the gravity suction type automatic sandblasting machine

- Overview of environmentally friendly sandblasting machine

- Overview of dry rust removal and sandblasting machine

- Talking about the main process parameters of the automatic sandblasting machine

- Classification of dry rust removal sandblasting machine

- Several environmental protection methods for rust removal and sandblasting machine