Working principle of environmental protection and energy saving sandblasting machine for pipeline rust removal

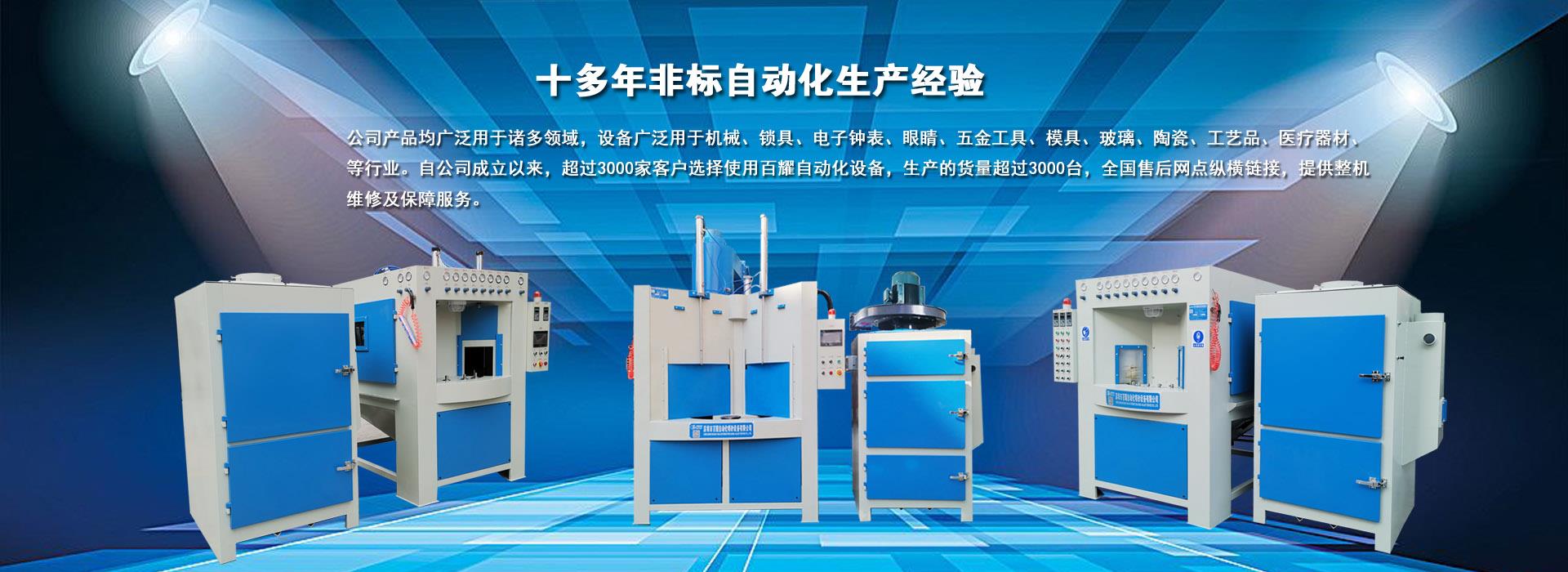

Pipe derusting developed by Baiyao AutomationEnvironmental protection and energy saving sandblasting machineIt is not only in line with the trend of market development, but also in response to energy conservation and environmental protection policies. This is because at present, in the domestic sandblasting machine market, there is still a relatively lack of such automatic sandblasting and rust removal devices that can simultaneously meet the pipeline rust removal requirements and environmental protection standards. For a long time, foreign sandblasting machine manufacturers have monopolized the high-end technology and products of automatic sandblasting and rust removal of pipelines. In order to break this monopoly, domestic manufacturers have invested heavily in research and development of related technologies and products. The rust-removing environmental protection and energy-saving sandblasting machine was born under this background. Here is a brief introduction to the working principle of this equipment.

The working principle of the environmentally friendly sandblasting and rust removing machine: The nozzle of this type of sandblasting machine is different from the traditional automatic sandblasting machine, and it adopts a special nozzle design. It is to install a semi-closed cavity outside the sandblasting gun head, and then put a hard brush on the cavity, so that the hard brush can be tightly attached to the surface of the workpiece when it is working, and in addition The negative pressure recovery port of the rust environmental protection energy-saving sandblasting machine is connected with the vacuum pump to draw back air to form negative pressure in the semi-closed cavity. Under the action of negative pressure, the steel grit sprayed by the sandblasting gun head will return to the sand storage tank through the negative pressure recovery port after high-speed impact on the surface of the workpiece. The recycled steel grit will be separated by dust in the rust removal environmental protection and energy-saving sandblasting machine. The steel grit will fall into the sand storage tank due to gravity, and the separated dust and dirt will be dedicated The treatment device is collected in it, and then the dust and dirt are filtered through a professional filter element, and then discharged.

The pipeline derusting environmental protection and energy-saving sandblasting machine developed by Baiyao Automation has not only greatly improved the pipeline operating environment when faced with such a complex and special environment as the pipeline derusting and cleaning operation, it has made the operating environment more healthy for humans. The threat is greatly reduced, and the quality of rust removal, sandblasting and work efficiency are also improved. Therefore, this derusting environmentally friendly energy-saving sandblasting machine will definitely shine in the future market.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- The risk of sandblasting the workpiece in the bottle in the rotary automatic sandblasting machine

- Working principle and use method of anti-skid automatic sandblasting machine for automobiles

- Overview of anti-skid automatic sandblasting machine for automobiles

- Design of Three Closed Loop Control System of Environmental Protection and Energy Saving Sandblasting Machine

- Design background and motion system of environmental protection and energy saving sandblasting machine

- Introduction to the main process parameters of the rotary automatic sandblasting machine

- Structure of mobile sandblasting machine for steel surface

- The working principle of remote control double cylinder double bridge mobile sandblasting machine

- Overview of vertical automatic sandblasting machine

- Overview of sponge abrasive automatic sandblasting machine