The risk of sandblasting the workpiece in the bottle in the rotary automatic sandblasting machine

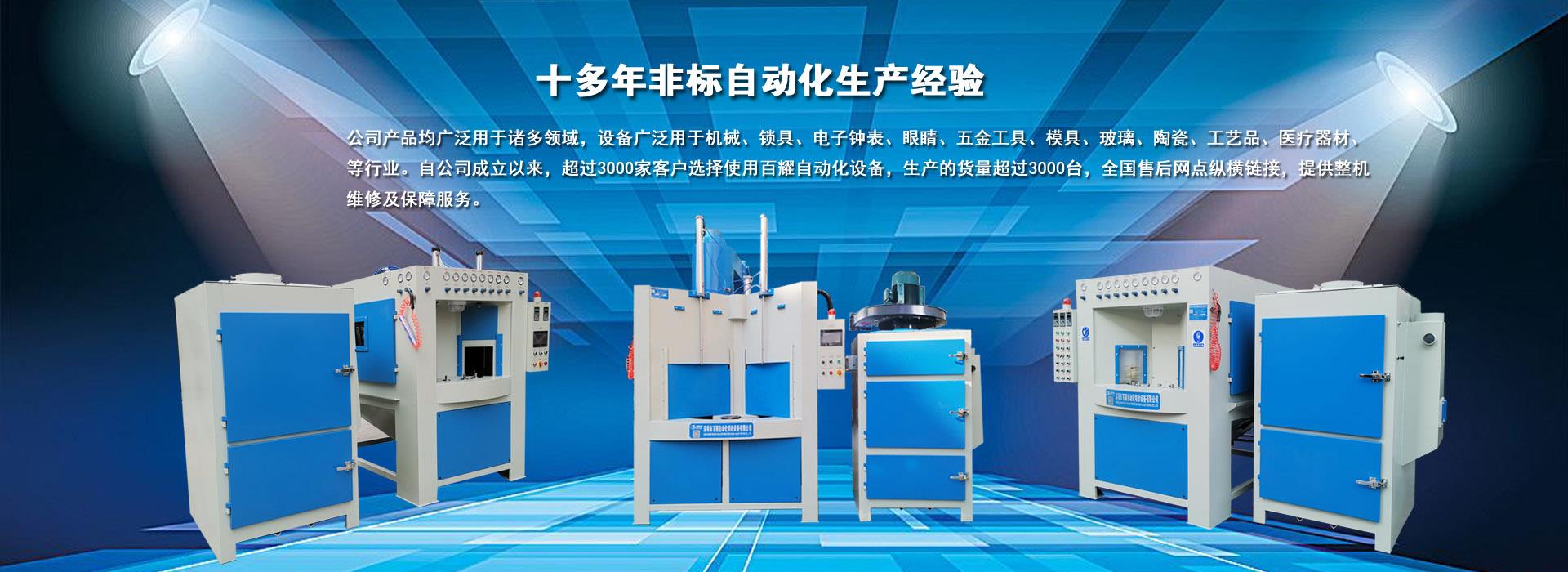

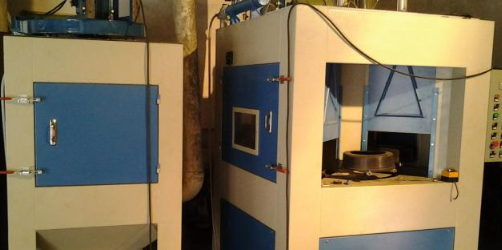

Turntable automatic sandblasting machineAt present, when performing intracavity sandblasting on small workpieces such as bottles, the operation is generally carried out in a sandblasting box. The operator uses rubber gloves to control the sandblasting nozzle to align the inner surface of the workpiece cavity outside the box. The sand particles will hit the inner surface of the workpiece cavity at high speed under pressure, so that the rotary automatic sandblasting machine generates cutting force , To remove the oxide scale on the surface of the product. At the same time, this cutting force will also have a certain cutting effect on the body material of the workpiece. The cutting amount is related to the hardness of the medium, the intensity of the sandblasting, the distance between the sandblasting port and the workpiece, the angle between the sandblasting port and the workpiece, and the sandblasting time. However, due to the structural characteristics of the bottle workpiece, there are certain risks in the process of sandblasting by the conveyor automatic sandblasting machine, mainly in the following two aspects:

Firstly, due to the small mouth of bottle-like workpieces, the inner cavity of bottle-like workpieces cannot be directly visually observed during sandblasting by the rotary sandblasting machine, and the personal experience of the operator can only be relied on during sandblasting. The short distance between the sand port and the workpiece, the large angle between the sand blast port and the cutting surface, and the uneven sand blasting area affect the quality of the blasting of the workpiece by the rotary automatic sand blasting machine.

The second is due to the restriction of the sandblasting box structure of the rotary automatic sandblasting machine. During the sandblasting process, it is necessary to hold the bottle while controlling the nozzle of the sandblasting. However, because the bottle workpiece has only one inlet and outlet, the abrasive cannot be discharged. This will affect the sandblasting effect at the bottom of the bottle on the one hand, and on the other On the one hand, as the abrasive accumulates more and more in the bottle, the weight of the bottle becomes heavier and heavier, making the operation of the operator more and more difficult, resulting in the possibility that the sandblasting nozzle of the rotary automatic sandblasting machine is too close to the workpiece. The blasting time in some areas is too long and other problems, resulting in the quality defect of excessive local cutting of the workpiece.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- Working principle and use method of anti-skid automatic sandblasting machine for automobiles

- Overview of anti-skid automatic sandblasting machine for automobiles

- Design of Three Closed Loop Control System of Environmental Protection and Energy Saving Sandblasting Machine

- Design background and motion system of environmental protection and energy saving sandblasting machine

- Introduction to the main process parameters of the rotary automatic sandblasting machine

- Structure of mobile sandblasting machine for steel surface

- The working principle of remote control double cylinder double bridge mobile sandblasting machine

- Overview of vertical automatic sandblasting machine

- Overview of sponge abrasive automatic sandblasting machine

- Introduction of rotary automatic sandblasting machine