Dust removal status of automatic sandblasting machine

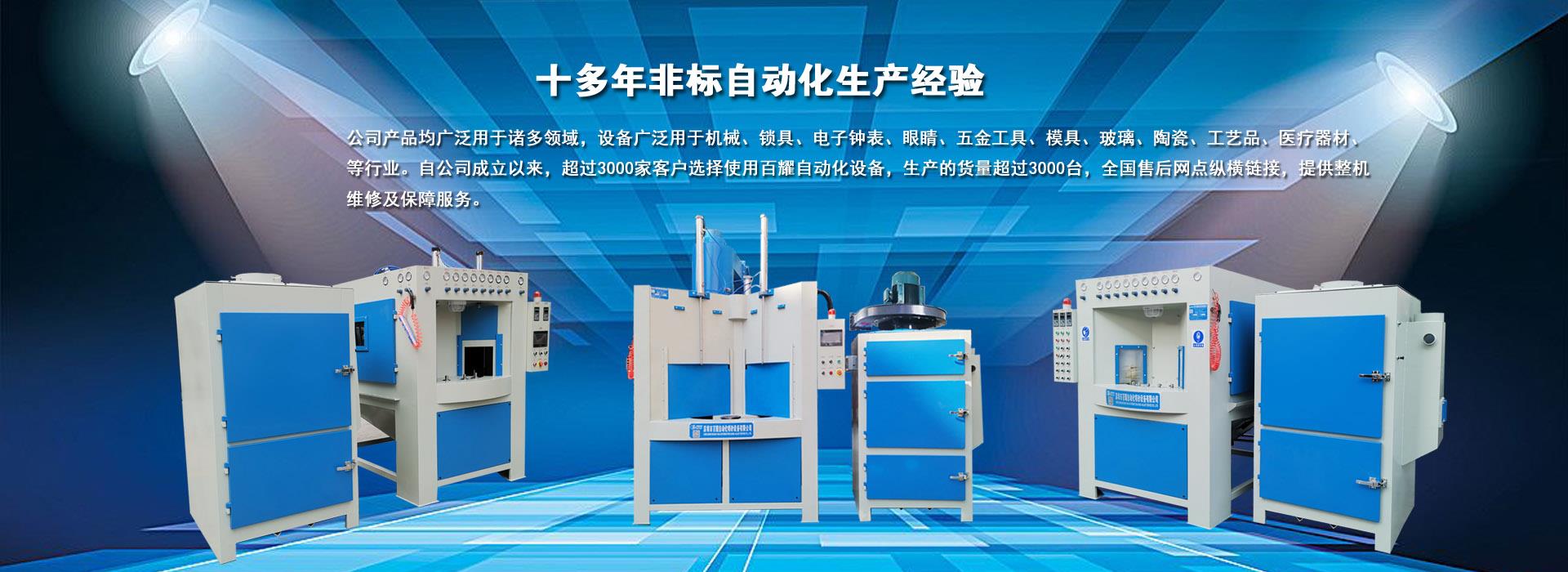

At present, all sandblasting plants across the country use dryAutomatic sandblasting machineInstead of the ancient manual sandblasting process. This significantly improves the efficiency of sand blasting and greatly reduces the labor intensity of sand blasting. However, the automatic sandblasting machine is prone to generate a large amount of dust during the working process. In this regard, all sandblasting plants have adopted dust removal measures to reduce the pollution of the dust to the environment and the harm to the constructors. The main dust removal measures can be summarized as follows:

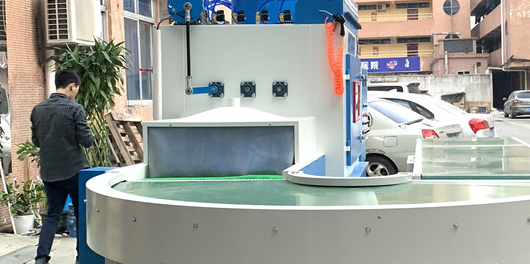

First of all, in order to limit the quartz sand dust to a local area as much as possible, the automatic sandblasting machine is equipped with a closed cover. There are two main types of sealing: one is to seal the automatic sandblasting machine with an ordinary closed cover. The hood makes the sand blasting volume smaller, and there is no buffer space for the airflow inside, so there is often a problem of large amount of sand. The sandblasting room is divided into two parts with a partition wall, so that the sandblasting machine is located on both sides of the partition wall, and the operation port is located on the side with less dust in the air.

Secondly, the dust removal method of the automatic sandblasting machine tends to use dry dust removal. Although wet dust removal has a good effect, it is difficult to clean the mud, and it is often difficult to discharge mud and dust accumulation, which makes the system paralyzed. At the same time, wet dust removal is in danger of freezing in the northern winter. However, a bag filter is required when using dry dust removal. Because after changing to a fully automatic sandblasting machine, the amount of compressed air required increases greatly, and the amount of quartz sand dust generated becomes larger.

In addition, it should be noted that the automatic sandblasting machine will have the following problems when using the bag filter for dust removal: First, the daily maintenance workload is large, and the working conditions are bad when changing the bag. The second is that the bag filter is installed outdoors. In the northern area, it is easy to condense in winter, and the phenomenon of bag sticking occurs. The resistance is greatly increased, and the corresponding air volume is reduced. Even the automatic sandblasting machine emits white sand, and some users are even forced to take the bag in winter. Do not use it.

Related News

- Low energy consumption of small sandblasting machine

- Derusting and sandblasting machine uses compressed air as power

- Sandblasting machine manufacturers generally supply sandblasting machines

- The mobile sandblasting machine uses the power, flow rate and flow of compressed air

- The working principle of wet sandblasting machine uses sandblasting abrasive and liquid as the medium

- Environmental protection and energy saving sandblasting machine supporting requirements

- Conveyor automatic sandblasting machine adopts suction sandblasting

- The nozzle of the rotary automatic sandblasting machine adopts special high wear-resistant boron carbide material

- The composition of the pipe end thread mobile sandblasting machine

- With timing automatic sandblasting, inching positioning function

- Composition of mobile sandblasting machine

- Analysis of common design problems of mobile sandblasting machine

- What are the factors that cause the uneven sand density of the automatic sandblasting machine

- Points to note when buying a fully automatic sandblasting machine

- Analysis of problems existing in dry mobile sandblasting machine

- The problems faced by the rust removal sandblasting machine process

- Talking about the working process of conveying automatic sandblasting machine

- Talking about the characteristics of rotary automatic sandblasting machine

- Factors affecting the effect of wood automatic sandblasting machine

- Overview of automatic wood sandblasting machine